The Frame of a Genius

The MCipollini carbon monocoque frame is the result of the perfect symbiosis between raw materials and human skills. Our production chain is extremely strict and comprises a series of experiences that come together to achieve unexplored goals. The lamination and painting department coordinates with the graphics and mechanisation sections of the R&D department in Verona. The excellence of carbon lamination, and its state-of-the-art and safety levels, is also verified by our Italian technicians at the Cipollini Bike Center in Bosnia.

Year after year, race after race, MCipollini's research continues to push the boundaries of its excellence. The desire to excel, the patience of craftsmen, method and intuition, technique and talent, turn the unfinished forms into the Frame of a Genius: the monocoque frame around which the magnitude of the MCipollini bicycles is created.

FEATURES

TCM, THE FRAME OF A GENIUS

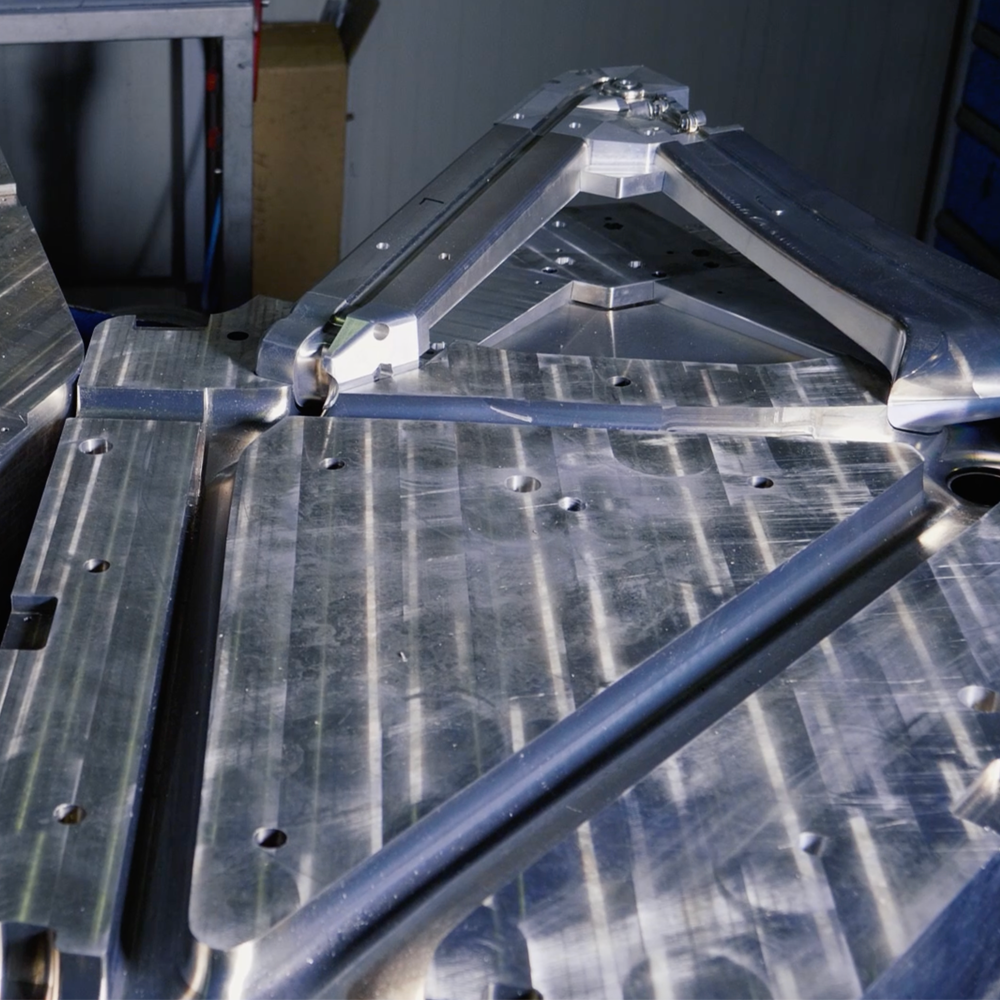

The TCM frame is made from one single mould, which entails a long and complex process. The carbon elements are positioned and layered inside an aluminium mould to achieve the maximum result. This means that the lamination process produces a single piece that does not undergo any further structural processing or subsequent firing that could alter the frame structure.

WHY IT'S UNIQUE

The MCipollini true TCM monocoque frame eliminates many of the weak spots of the other monocoque frames on the market, which are often achieved by using adhesives to fasten the front and back of the frame together. This treatment makes the frame structure more prone to deterioration in the long term, resulting in a decrease in performance. TCM's monocoque structure, however, tends to absorb the pressures on the frame more evenly and with less impact, promoting a longer durability over the years. Stronger, tougher, lighter: this is why the MCipollini frame is The Frame of a Genius.

FROM RAW MATERIALS TO PROCESSING

The choice of the fibres used in the lamination, their certification and the autoclave construction technology bestow unique mechanical characteristics to the MCipollini frames. The materials used in the manufacturing process are pre-impregnated with epoxy matrix resins and undergo sequential checks to ensure that the resin content is uniform on all the various parts.